Copyright © 2024 Qingdao Pristine Steel Structures and Engineering Co.Ltd All Rights Reserved.  Powered by Hicheng

Powered by Hicheng

Article Navigation

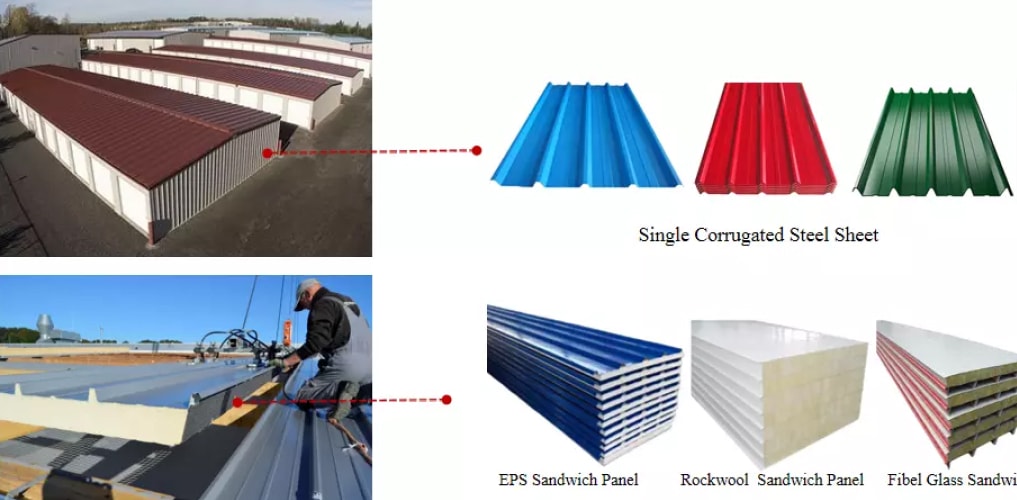

Single corrugated steel sheet is a widely used building material. It is mainly made of cold-rolled steel substrates, hot-dip galvanized steel substrates, or electro-galvanized steel substrates. These substrates undergo surface degreasing, phosphating, and chelating treatment, followed by the application of organic coatings and baking.

Color steel plate boasts numerous advantages. Firstly, it is lightweight, approximately one-thirtieth the weight of brick walls, facilitating easy handling and installation. Secondly, it exhibits excellent thermal insulation properties, suitable for various climatic conditions. Furthermore, its high strength allows it to be used as a load-bearing material for enclosure structures, resisting bending and compression. Additionally, the flexible and rapid installation of color steel plate shortens the construction period, significantly improving construction efficiency. Finally, its vibrant and long-lasting colors can maintain a corrosion-resistant layer for up to 10-15 years.

In the construction sector, it is commonly used for roofing, walls, and doors in industrial and commercial buildings such as steel structure factories, airports, warehouses, and cold storage facilities.

The sandwich panel consists of inner and outer face sheets and a core material. The face sheets are typically made of metal, wood, or plastic, while the core material can be various materials such as rock wool, polyurethane, and glass wool. This construction gives the composite board remarkable physical properties.

1. High Strength:

2. Excellent Thermal Insulation:

3. Outstanding Sound Insulation:

4. Superior Fire Resistance:

Due to these advantages, composite board is widely used in construction, decoration, transportation, and other fields. In the construction industry, it is commonly used for roofs, walls, partitions, and other parts, offering both aesthetics and practicality.

-If there is no heat or sound insulation needs, then single steel sheet will be enough, the cost and freight fee will be lower. If the local temperature is pretty high or low, or there is a sound insulation requirement, then sandwich panel will be a better choice.

What are the commonly used colors?

Normally white or white gray for wall panel, ocean blue or white gray for roof panel. As these colors are frequently used, the cost will be lower and delivery date will be shorter than customized colors.

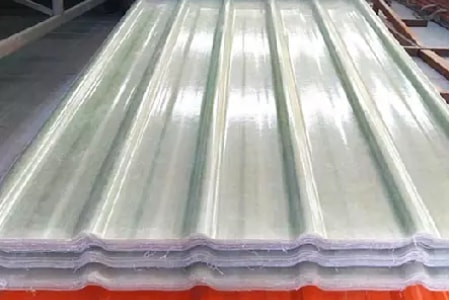

Installing daylighting belts on warehouse roofs mainly aims to enhance indoor lighting, improve the working environment, and help save energy and reduce electricity expenses.

There are V760,V820, V840,V920,V950,V980, normally V840 is often used.

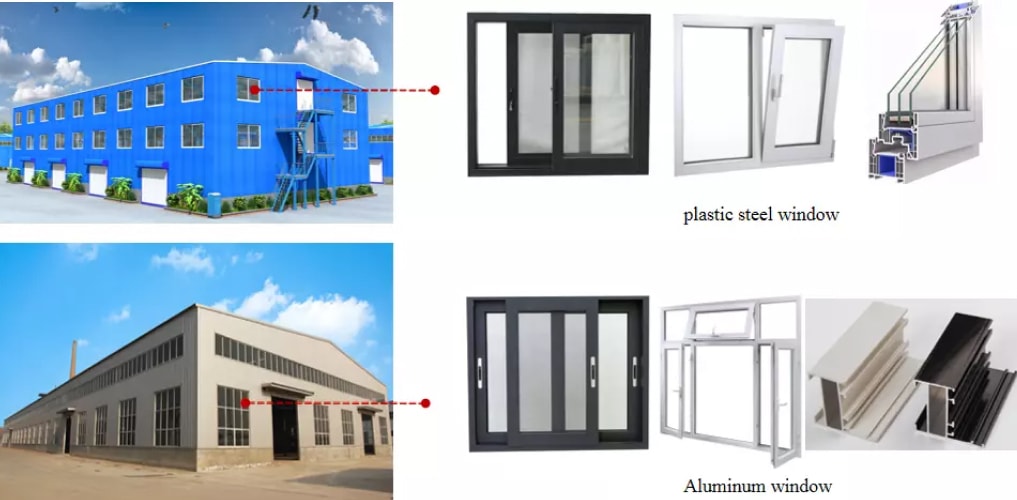

plastic-steel windows are primarily composed of plastic, typically using polyvinyl chloride (PVC) resin as the main raw material. Stabilizers, colorants, fillers, and UV absorbers are added in certain proportions, and the material is extruded into profiles.

plastic-steel windows excel in thermal insulation due to the low thermal conductivity of plastic. Heat is less likely to be conducted through the material, resulting in excellent warmth retention in winter and heat insulation in summer.

Plastic-steel windows, on the other hand, are relatively more affordable, making them a suitable choice for budget-conscious renovation projects.

Aluminum alloy windows, on the other hand, are made from aluminum alloy frames and sashes, offering high strength, resistance to deformation, and excellent wind pressure resistance. Aluminum alloy windows, with their higher thermal conductivity, have relatively poorer thermal insulation performance. Additionally, plastic-steel doors and windows also offer better sound insulation, effectively reducing noise transmission.

aluminum alloy windows tend to be more expensive due to their manufacturing process and higher material costs

-It depends on actual situation, if there is no specific requirement, then plastic steel windows will be suggested.

Roof ventilation balls are ventilation devices installed on the roof of buildings. Their primary function is to promote indoor air circulation, exhausting hot air, moisture, and harmful gases from the interior, thereby improving the indoor environment and air quality. The ventilation balls are typically spherical and achieve rotational motion through natural wind forces or mechanical devices, creating a negative pressure effect that facilitates air exchange between the indoors and outdoors. This equipment not only helps reduce indoor temperatures and improve worker efficiency, but also minimizes stale and unpleasant odors, safeguarding the health of employees.

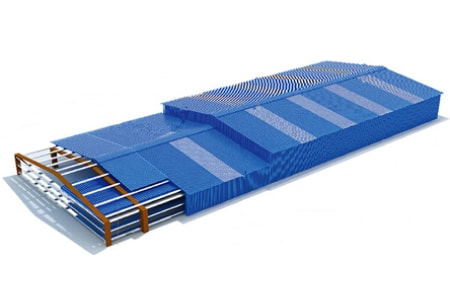

In a steel structure warehouse, the mezzanine refers to a secondary floor or level constructed within the warehouse space. It is typically supported by steel beams or columns and is designed to provide additional storage or workspace. The mezzanine can be customized to fit the specific needs of the warehouse, such as the height, layout, and loading capacity. This innovative design effectively utilizes vertical space, enhancing the overall storage capacity and operational efficiency of the warehouse.

In a warehouse with a mezzanine, a lifter, often referred to as a lift or elevator, is crucial for efficient vertical transportation. This mechanical device allows personnel and materials to be safely moved between the ground level and the mezzanine level. The lifter typically consists of a platform or cage, which is raised and lowered by mechanical means such as cables or hydraulics. Its use significantly improves the workflow and productivity in the warehouse.